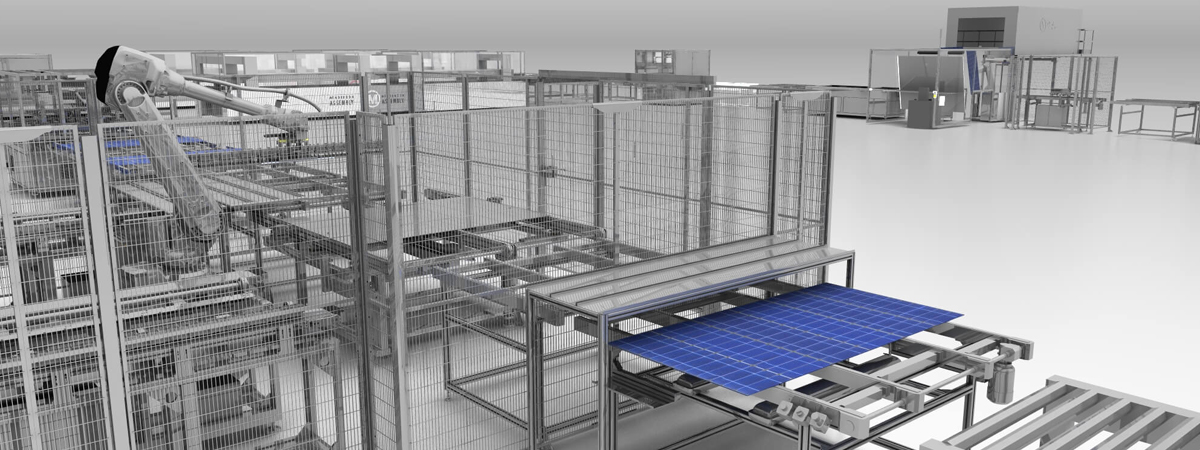

Solar panel technology is advancing rapidly with greater efficiency and lower prices resulting in a huge increase in demand. However, despite the massive advancements in technology, basic solar panel construction hasn’t changed much over the years. Most solar panels are still made up of a series of silicon crystalline cells sandwiched between a front glass plate and a rear polymer plastic back-sheet supported within an aluminium frame.

Once installed, solar panels are subjected to severe conditions over the course of their 25+ year life. Extreme variations in temperature, humidity, wind and UV radiation can put enormous stress on a solar panel. Fortunately, most panels are well engineered to withstand the extreme weather. However, some panels can still fail in several ways including water ingress, cell micro-fractures and potential induced degradation or PID. This is why it’s vital solar panels are manufactured using only the highest quality components. In our other article, we highlight the leading manufacturers using the highest quality materials together with testing to the highest industry standards. See the guide to selecting the highest quality solar panels.